About the ZYCOR ANALYZERS

NO/ H2O

Using the same in-situ probe unit design as the SO2/NO2/CO2 sensor the NO/H2O sensor uses a similar measurement principle of determining the absorption of radiation energy to determine the concentration of both NO and H2O in the probe measurement cell. This sensor however uses a Quantum Cascade Laser (QCL) as the source of radiation.

NO is traditionally difficult to measure. The standard technique is that of chemiluminescence whereby the gas is oxidised to NO2 by mixing with ozone and the subsequent UV emissions resulting from the NO2 relaxing to a ground state is measured to deduce the NO concentration. This process is highly maintenance intensive.

Numerous analysers are also available using IR absorption spectroscopy. A major problem results from the NO IR absorption spectrum being heavily overlapped by that of H2O leading to huge cross sensitivities to H2O. UV absorption is also sometimes used for the determination of NO, but has the disadvantage that the NO UV spectrum is at very short wavelength UV where the UV lamps capable of producing such radiation have a short lifetime, requiring frequent replacement and instrument recalibration.

The use of a QCL overcomes all such difficulties. The QCL used in the Zycor sensor emits a very narrow and precise beam of infra-red energy which enables a single NO absorption line, within its absorption band, to be scanned by the laser. A suitable absorption line can be chosen which is free from H2O interference thus enabling an accurate determination of NO concentration to be made. The wavelength of the emitted QCL radiation can be varied by accurate control of the laser temperature enabling the single NO absorption line to be scanned to produce a very stable, noise free, accurate measurement of the NO concentration, free from other gaseous interference. This same laser also measures the H2O concentration by monitoring an H2O spectral line adjacent to the NO line.

The sensor is capable, without modification or rescaling, of measuring NO levels varying from less than 10ppm to several thousand ppm at temperatures up to 450degC. In common with the SO2 sensor the NO sensor has no moving components and requires zero maintenance. QCLs are noted for very high reliability with mean time between failures measured in tens of years.

While the current QCL sensor is designed for the measurement of NO, the sensor is readily adaptable for the measurement of other difficult to measure gases by changing the QCL for one with emission wavelengths appropriate for the gas in question. For example, low concentrations of NH3 can be easily measured by selecting a QCL emission wavelength appropriate to the NH3 absorption band around 9 micrometres, making it eminently suitable, along with the NO sensor, for the monitoring and control of plant for the Selective Catalytic Reduction of NO on coal fired power plant.

Feature

⬢ IN-SITU CEMS suitable for Refineries , power plant & other indutries.

⬢ Measurement gas resolution 1 PPM and accuracy +/-2% of reading.

⬢ Specifications at par with current Refinery specifications.

⬢ Safe Area/Hazardous area available.

⬢ UV absorption spectroscopy based SO2 & NO2 measurement , Laser (QCL) based NO & H2O measurement and Infrared spectroscopy-based CO2 measurement.

⬢ 24 VDC power supply operated.

⬢ Remote monitoring of system available.

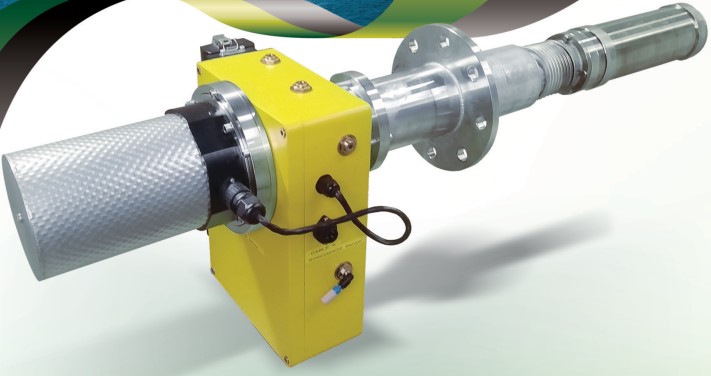

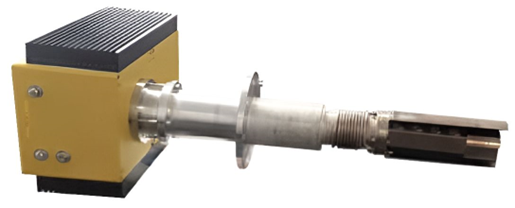

⬢ Simple Installation as per the photograph.

⬢ Light weight so easy to installation.

⬢ Low maintenance cost.

⬢ No Shelter required.

| Specification | NO | H2O |

|---|---|---|

| Range | 0 to 1000ppm | 0 to 20% |

| Resolution | 1ppm | 0.1% |

| Uncertainty of measurement | 1ppm or 2% of reading | 0.1% H2O |

| Response | 100 seconds | 100 seconds |

| Flue gas temperature | 0 to 450degC | 0 to 450degC |

| Ambient temperature | -20 to +50degC | -20 to +50degC |

| Power Requirements | 36V DC at 50VA | 36V DC at 50VA |

| Additional services | None required | None required |

| Data Output | RS485 | RS485 |